Significant operational savings thanks to VAPOL CZ warehouse automation

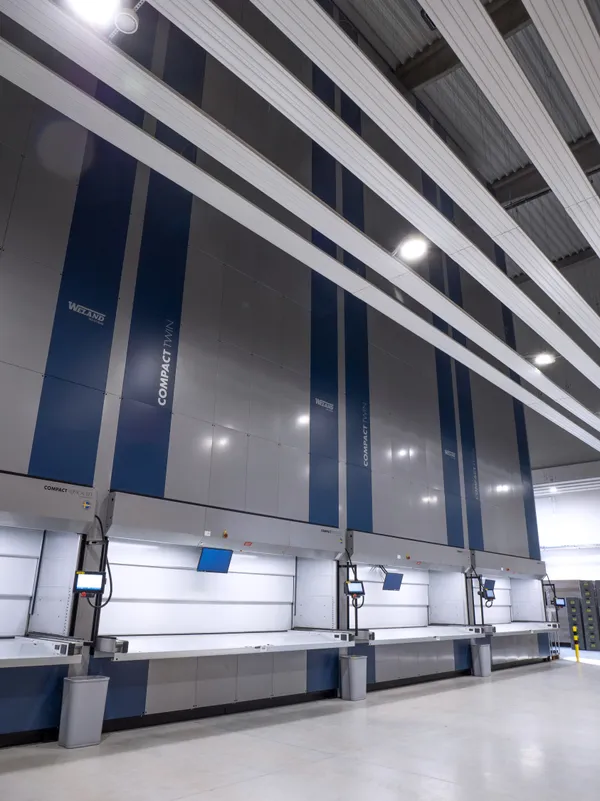

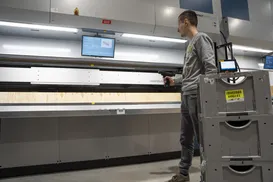

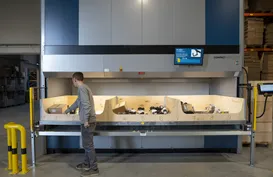

Founded in 1991, Vapol is a spare parts supplier specializing in towing devices and electrical installations. The assembly centre in Holešov has expanded its storage capacity by installing four Compact Twin vertical storage lifts and one Compact Lift vertical storage lift in Double Deep design. The double depth of the trays allows for the storage of large items such as towbars. The 3660 mm wide trays in all vertical storage lifts are equipped with plywood dividers in different sizes for clear distribution of goods of different sizes and have a load capacity of 300 kg.

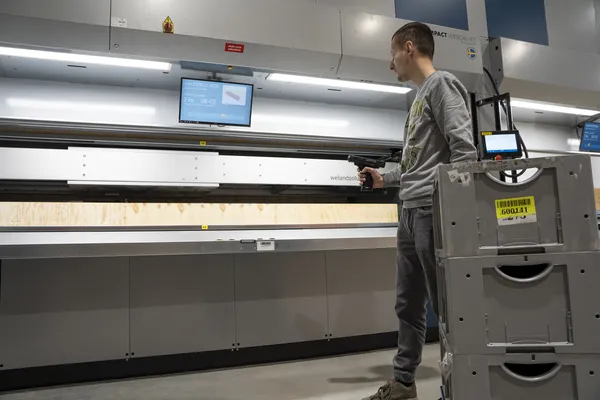

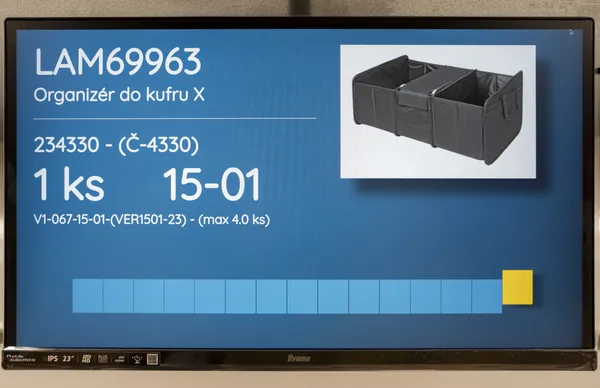

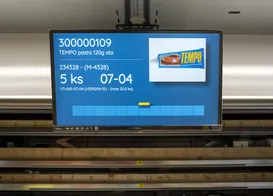

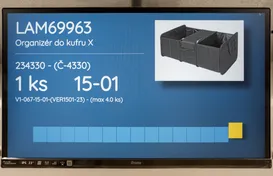

The vertical storage lifts, thanks to their storage height, reach an impressive 13826 mm, providing enough space to store 354 trays in different height ranges with a total storage area of over 1211 m2 and a load capacity of 117 tonnes. The vertical storage lifts are controlled by VertiNode Ai - a dedicated logistics software with artificial intelligence that optimises processes and manages picking operations.

In a smaller footprint than conventional racking, the vertical storage lifts offered four times the storage capacity and increased the productivity of logistics operations by 4 times. In the previous arrangement, 250 shipments could be handled per shift and now up to 1,000 orders can be handled. There has been a significant streamlining of picking and it is possible to process 255 lines per hour, picking an item every 16 seconds. This has brought significant financial savings. There has been a 40% saving in human resources and a reduction in the number of warehouse staff from 14 to 8.