Madal Bal warehouse automation

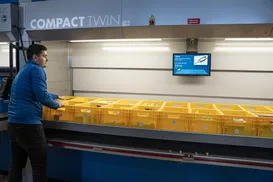

We have delivered four Compact Twin vertical storage lifts to Madal Bal, a Czech company specialising in e-commerce, import and distribution of tools. The cladding of the machines has an individual design in Madal Bal blue with a unique coating. This is one of our advantages - we can supply the cladding in company’s corporate colours or with a unique design according to customer requirements.

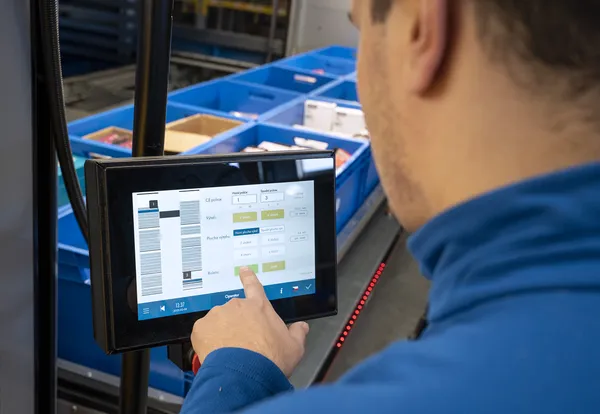

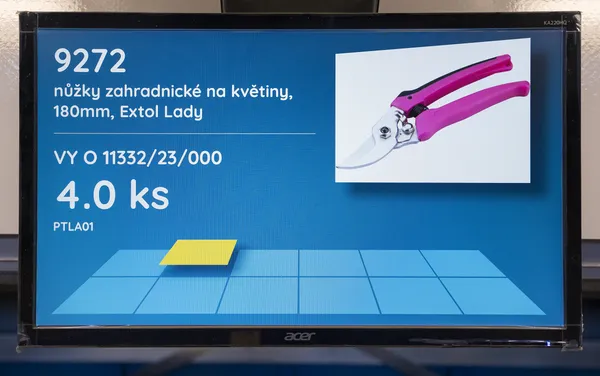

The Compact Twin vertical storage lifts are equipped with a monitor to display the picked item with a description and indication of the position on the tray. Combined with the light bar, it greatly facilitates operator orientation and speeds up the process of picking a specific item and quantity. These features eliminate the likelihood of picking errors to the maximum extent possible. Completed picking of a specific item is confirmed by one of four coloured buttons, which are always assigned to a specific worker, allowing up to four operators to work simultaneously. A handheld rack equipped with a Pick-to-Light bar is added to the picking process, where up to ten orders can be picked simultaneously into prepared bins. Complete picked orders are transferred to the shipping department.

The VertiNode Ai software controls the communication between the vertical storage lifts and the entire goods handling process from loading to storage and picking. It is a dedicated automated logistics software with the latest artificial intelligence technology that is compatible with most warehousing systems and equipment, including competitors. VertiNode Ai is also linked to the warehouse management system (WMS) in Madal Bal. The loading of goods and their subsequent picking is thus managed using artificial intelligence (Ai), which optimises the maximum capacity utilisation of individual vertical storage lifts over time based on data from the WMS system.